September 9, 2021

How to Run Pipes Through Walls and Floors for DIY Plumbing Work

Remodeling your bathroom? Read this before running any pipes. We'll show you how to navigate tricky spots through the wall and floor.

The pipes that power faucets, showers, toilets, and other fixtures are typically hidden behind walls or underneath floors, a setup that requires careful planning to install properly. Once you've drawn a plan for new plumbing service, it's important that you also develop a strategy for running the pipes. In a new building or addition where the framing is exposed, this is easy. If you are remodeling a bathroom or kitchen, be prepared to make changes in the plan once you've removed the wall covering and flooring.

Replacing finished surfaces after plumbing (especially patching walls) usually takes several days. Repairing a large wall patch (or even replacing an entire wall) takes only a little more time than a small patch, so open plenty of space for working.

Once you've opened the vent and drain lines, running the supplies, which usually run alongside drain-waste-vent (DWV) lines, will be relatively easy. Before you begin, brush up on basic carpentry skills, understand your home's structure, and make sure you know how to install pipe. It's also a good idea to get your plan approved by the local building department to make sure it adheres to plumbing codes.

Replacing finished surfaces after plumbing (especially patching walls) usually takes several days. Repairing a large wall patch (or even replacing an entire wall) takes only a little more time than a small patch, so open plenty of space for working.

Once you've opened the vent and drain lines, running the supplies, which usually run alongside drain-waste-vent (DWV) lines, will be relatively easy. Before you begin, brush up on basic carpentry skills, understand your home's structure, and make sure you know how to install pipe. It's also a good idea to get your plan approved by the local building department to make sure it adheres to plumbing codes.

How to Run Pipes Through Walls and Floors

Any remodeling project, home addition, or new construction that involves plumbing work will generally involve running pipe. Learn how to navigate tricky spots through walls and floors with these instructions.What You Need

- Demolition tools

- Drill with various bits and hole saws

- Reciprocating saw

- Level

- Pipes

- Pipe fittings

- Clamps

Step 1: Assess and Remove the Wall

If you need to run a new stack, assess your framing. An installation with a toilet must have a 3-inch drain, which can be installed only if the stud wall is made of 2x6s or larger (2-inch pipe can be run through a 2x4 wall). Remove the wall surface up to the ceiling.

Step 2: Prep for New Pipe

Cut a hole with some wiggle room for the new pipe. For a 3-inch pipe, use a drill and reciprocating saw to cut a hole about 4-1/4 inches by 10 inches through both the bottom plate of the room you are working in and the top plate of the room below. Cut away a 10-inch by 2-foot section of flooring.

Step 3: Assemble and Place Drainpipe

Assemble the approved fittings onto the top of the drainpipe. Take special care that they face the right direction. The drainpipe should be longer than needed; you can cut it to size from below later. Slip the pipe down through the hole.

Step 4: Run the Vent

You might need to cut a hole in the wall of the room above or below to guide the vent pipe up or the drainpipe down. In the attic, you might be able to run the vent over to tie into an existing vent. If not, drill a hole in the attic ceiling and have a roofer install a roof jack for the vent pipe.

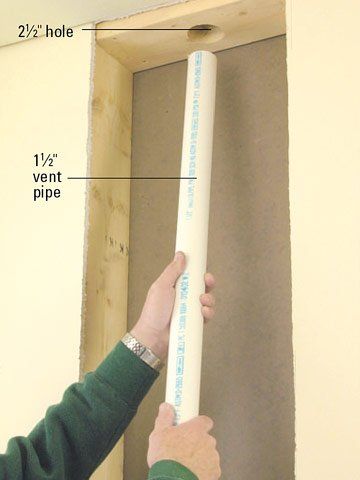

Step 5: Guide and Attach Pipes

Anchor the drainpipe with straps. Cut a smaller opening in the ceiling for the vent pipe. For a 1-1/2-inch vent pipe, a 2-1/2-inch hole is sufficient. Guide the vent pipe up through the hole and into the attic or room above and slip its lower end into the fitting at the floor.

How to Stabilize and Protect Pipes

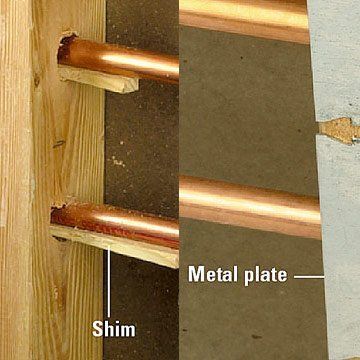

Whenever possible, run pipes through holes in the center of framing members. To keep pipes from rattling, line the holes with felt or use wood shims. Slip a shim under the pipe and tap in until it is firmly in place, but not tight, to allow for expansion. If notches are needed, make them as small as possible; they weaken the framing member. You can also use metal plates to protect pipes from nails.

Tips for Running Pipe Through a Floor

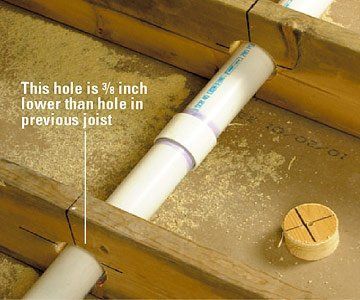

Running drainpipe through joists calls for meticulous work. The holes must follow a straight line across the floor and must ascend or descend so the pipe will be sloped 1/4 inch per foot. (If joists are 16 inches on center and pipes run across them at a right angle, holes should differ in height by about 3/8 inch.)

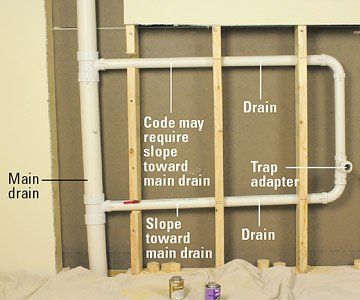

Tips for Running Pipe Through a Wall

Vent pipes might run level, although some codes call for a slight slope toward the main drain. All drain lines must be sloped. For a precise slope, strike a level line on the studs and measure down 1/4 inch per running foot. Note that codes might also call for fireproof caulking in walls.Source: https://www.bhg.com/home-improvement/plumbing/how-to-run-pipes-through-walls-and-floors/